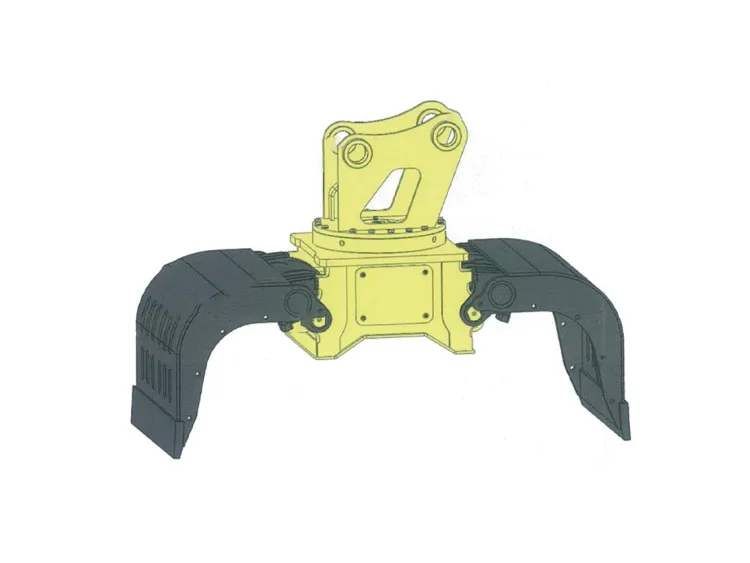

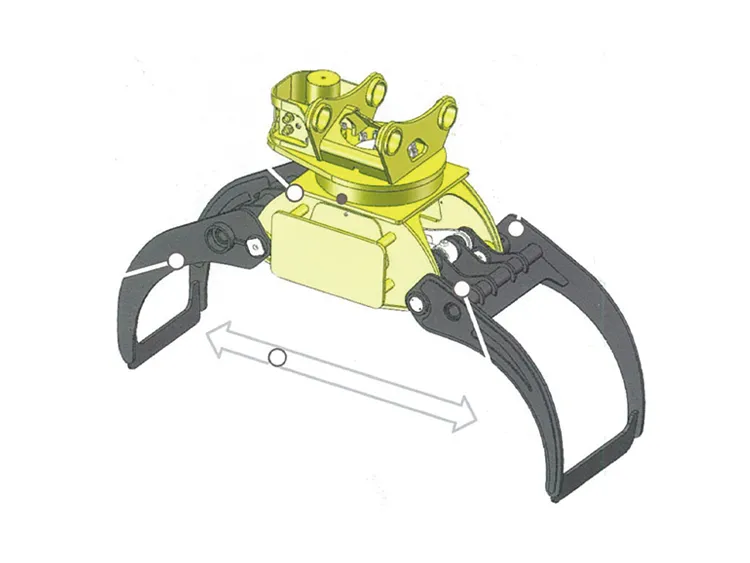

Orange Peel Grapple/Steel Scrap Grab

Optimizing the movement of oil cylinder can maximize the grabbing weight within the effective grabbing range and there by shorten the machine running time, which improves work efficiency.

The design of the claw structure is optimized to realize the minimum weight and maximum grab load at the same level.

The specially designed meshing gear improves the bearing strength of gear. the load distribution during movement, the accuracy and stability of the transmission.

The specially designed oil separator and flow control valve ensures the stability and synchronization ofthe entire hydraulicsystem.

The special wear-resistant steel plate welding process not only improves the wear resistance of the claw, but also ensures the overall welding quality.

Specifications

| Specifications | JWB06H | JWB08H | JWB10H |

| Maximum Openning (mm) | 1650 | 1850 | 2050 |

| Weight (kg) | 800 | 1250 | 1530 |

| Operation Pressure(Closed) (kg/cm2) | 140-180 | 160-200 | 160-200 |

| Operation Flow (Closed) (L/min) | 80-120 | 100-140 | 130-180 |

| Operation Pressure (Rotating) (kg/cm2) | 80-120 | 80-120 | 80-120 |

| Operation Flow (Rotating) (L/min) | 30-50 | 30-50 | 30-50 |

| Grab Weight (kg) | 1000 | 1400 | 1500 |

| Number of Peels | 5 | 5 | 5 |

| Suitable Carrier (ton) | 10-16 | 17-24 | 25-35 |

| Specifications | JWB06 | JWB08 | JWB10 |

| Maximum Openning (mm) | 1650 | 1850 | 2050 |

| Weight (kg) | 800 | 1250 | 1530 |

| Operation Pressure(Closed) (kg/cm2) | 140-180 | 160-200 | 160-200 |

| Operation Flow (Closed) (L/min) | 80-120 | 100-140 | 130-180 |

| Operation Pressure (Rotating) (kg/cm2) | 80-120 | 80-120 | 80-120 |

| Operation Flow (Rotating) (L/min) | 30-50 | 30-50 | 30-50 |

| Grab Weight (kg) | 1100 | 1500 | 1700 |

| Number of Peels | 5 | 5 | 5 |

| Suitable Carrier (ton) | 10-16 | 17-24 | 25-35 |

Keywords

Orange Peel Grapple/Steel Scrap Grab(H type)

Classification